Kenneth Michael Guitars est.1978

"Masterwork Cam Clamp Kit"©

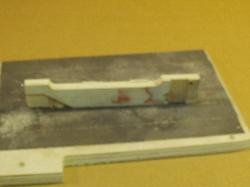

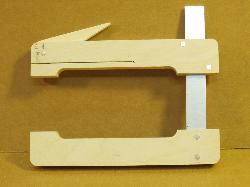

Our “Masterwork” Cam Clamp Kit is unique in the industry. Each kit yields

three high quality clamps with an 8” deep throat and 5 ½” open height.

They are made from birch plywood, hardwoods and use light weight

aluminum or hardwood for the slide bar.

three high quality clamps with an 8” deep throat and 5 ½” open height.

They are made from birch plywood, hardwoods and use light weight

aluminum or hardwood for the slide bar.

Assembly starts with cutting the

components from a sheet using a band

saw, saber saw etc. The parts are held

on the sheet with only a thin partial

tab layer.

components from a sheet using a band

saw, saber saw etc. The parts are held

on the sheet with only a thin partial

tab layer.

Each clamp requires two top section

halves, these have the slots for the

cams and two bottom section halves.

The bottoms only have slots for the

bar.

halves, these have the slots for the

cams and two bottom section halves.

The bottoms only have slots for the

bar.

The CNC machining leaves the components in a rough state on

the inside mating surfaces. Clean off the burrs with sanding

blocks, files, scrapers etc.

the inside mating surfaces. Clean off the burrs with sanding

blocks, files, scrapers etc.

Each clamp requires 4 – 1" x 1/4"

rivets and one 1 x 3/16” rivet

rivets and one 1 x 3/16” rivet

The bar needs to slide freely in the slot

created by the two top clamp halves.

Mate the parts temporarily insert the

pins and check for smooth movement.

File or sand proper clearance if

necessary.

created by the two top clamp halves.

Mate the parts temporarily insert the

pins and check for smooth movement.

File or sand proper clearance if

necessary.

When you are satisfied with the fit apply

“Titebond” glue to both halves, use

care not to get glue in the bar slot.

Apply several clamps to secure.

“Titebond” glue to both halves, use

care not to get glue in the bar slot.

Apply several clamps to secure.

Repeat the above procedure for the bottom halves of the clamp. Getting glue in

the bottom half bar slot is not a concern as long as the bar is flush with the lower

edge. The bar is ultimately pin in this location.

the bottom half bar slot is not a concern as long as the bar is flush with the lower

edge. The bar is ultimately pin in this location.

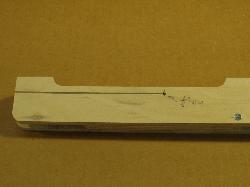

After the top half has dried – usually at least 30 minutes, mark a straight

line across the bottom of the cam slot.

line across the bottom of the cam slot.

Draw a line 5 ¼” long using the bottom

of the cam slot as a starting point.

of the cam slot as a starting point.

Drill a 1/8” hole as perpendicular as

possible – if you have drill press use it.

Locate the center of the hole at the end of

the line that was just drawn.

possible – if you have drill press use it.

Locate the center of the hole at the end of

the line that was just drawn.

This step is a little tricky if you do not have a band saw – a saber saw will work fine if

equipped with a fine cutting blade and if you do not rush. It is necessary to cut loose

the pressure pad along the line. Keep the blade on track and perpendicular. Check

the cut on the bottom as you progress – if doing the job with a hand held saw it may

be helpful to draw lines on both sides of the clamp to check how you are tracking with

the cut.

equipped with a fine cutting blade and if you do not rush. It is necessary to cut loose

the pressure pad along the line. Keep the blade on track and perpendicular. Check

the cut on the bottom as you progress – if doing the job with a hand held saw it may

be helpful to draw lines on both sides of the clamp to check how you are tracking with

the cut.

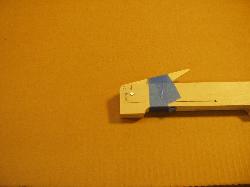

Tape the cam lever in the clamp slot aligning the rounded end to the front of the clamp.

Doing this will keep the parts in the correct position during the drilling operation.

Doing this will keep the parts in the correct position during the drilling operation.

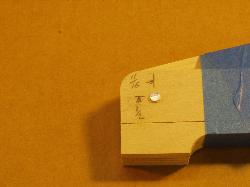

The cam lever is fastened to the clamp using the 3/16” rivet. A hole needs to be drilled

through the clamp half and the pin. The hole location is 11/16” from the from edge and ½”

from the top of the saw kerf. Mark this location and use a nail or an awl to punch a start

detent so the drill bit will not slip off location. Drill a perpendicular hole all the way

through. Install the 3/16" rivet -- place the clamp on a metal surface and tap a hammer to

seat a droplet of CA (Super glue) can be use if the fit is not tight.

through the clamp half and the pin. The hole location is 11/16” from the from edge and ½”

from the top of the saw kerf. Mark this location and use a nail or an awl to punch a start

detent so the drill bit will not slip off location. Drill a perpendicular hole all the way

through. Install the 3/16" rivet -- place the clamp on a metal surface and tap a hammer to

seat a droplet of CA (Super glue) can be use if the fit is not tight.

Using a ¼” bit drill through the aluminum

or hardwood bar--- again keep the drill

perpendicular as possible.

or hardwood bar--- again keep the drill

perpendicular as possible.

Place the clamp on a hard Insert the

pins in the holes and hammer in

through the bar. Keep the 1/4" rivets

perpendicular or they will get wedged

and have to be removed and started

over.

pins in the holes and hammer in

through the bar. Keep the 1/4" rivets

perpendicular or they will get wedged

and have to be removed and started

over.

The rivets can secured with a droplet of CA (super glue) if the fit is not tight.

© Bill Cory